Water & Air

General

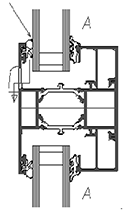

A pressure

adjusting glazing system, which is, amongst others, applied to

aluminium windows, starts from the principle that, after having

installed the pane, the peripherical margin is in direct

connection with the open air. With this kind of glazing system

ventilation- and drainage holes are necessary. Holes (Ø 8mm) or

grooves (5x25mm) need to be fixed in the inter-/bottom rail in

order to evacuate any water that may have gotten trapped inside.

The old solution

Until now drain caps were fixed onto the drainage holes-/grooves on the outside, which aesthetically speaking, defaces the overall picture. Moreover, in the course of time - due to many different kinds of causes - these caps could often come undone. And not only architects have a problem with this.

True enough, the majority of the profile suppliers carry a flat/small profile in their programme with an extra compartment on the front side, so that the water discharge can occur from underneath this compartment, and therefore without the drain-caps. However, such a profile is slightly more expensive than a normal flat profile and is only available in limited varieties and/or dimensions. In addition, the glass surfaces in such a frame element will differ from one another.